| |

Bioprom Pellet 150 kW Flare Pellet Burner

|

|

| |

|

|

| |

|

|

| |

|

|

| |

Burner Description And Operation |

|

| |

Purpose: |

|

| |

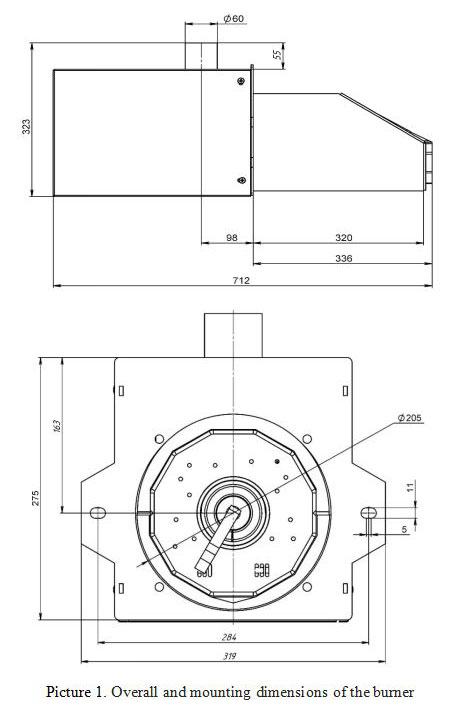

Burners of <<BIOPROM PELLET 150 KW>> type (Picture 1) are intended for burning wood fuel pellets in water-heating boilers with a nominal heat output of up to 150 kW. |

|

| |

|

|

| |

|

|

| |

|

|

| |

The design of the boiler on which the burner is installed shall meet the following requirements:

- The boiler shall be adapted for burning biomass, and its internal flow channels shall have full capability to exchange heat and exhaust emissions.

- The combustion chamber shall have dimensions allowing to install and remove the burner.

- The boiler's door shall have a hole with a size of 260X240 mm, the thickness of the boiler's door shall be not more than 100 mm; get a hold of the manufacturing plant for the boiler and obtain the advice, if required.

- The design of the boiler shall ensure the opening of the boiler's door with a burner for ash removal and cleaning. If the boiler's door is too narrow for opening along with the burner, the additional hinge straps shall be installed.

- If there is insufficient vacuum in the boiler (less than 5 Pa), it is required to install the fan exhauster to remove burnt gases.

- The boiler-house where the burner is installed shall correspond with all the acting local norms and rules.

- The boiler shall be located in such a way to ensure enough room for cleaning the burner and removing ash from the boiler and the chimney. If the flue gas temperature at the boiler outlet is less than 120 °C, there is a risk of condensation of water vapor in the chimney. |

|

| |

|

|

| |

CAUTION! It is prohibited to use the burners for other than the purpose specified as well as make any design changes of the burner without consent of the manufacturer |

|

| |

Performance Data |

|

| |

The basic performance data of the burner is described in Table 1 |

|

| |

|

|

| |

| Parameter |

Value |

| Heat power (adjustable), KW |

50...150 |

Fuel Characteristics:

diameter, mm

length

calorific value, KW•h/t

poured density, kg/m3

water content,%

ash content,% |

6...8

3...5 of diameter

4700...5100

CA 650...670 8...10

CA 0,5 |

| Power voltage, V/Hz |

220/50 |

Power consumption, KW:

Firing mode

Working mode |

325

45 |

| Efficiency, % |

90 |

|

|

| |

|

|

| |

|

|

| |

Delivery Set |

|

| |

The standard delivery set for the burner is described in Table 2 |

|

| |

| Burner as an assembly |

1 ea. |

| Burner control unit with sensor set and connecting wires |

1 set. |

| Flexible heatproof tube for connecting feeder to the burner |

2 ea. |

| Burner case |

1 ea. |

| Operation Manual |

1 ea. |

|

|

| |

|

|

| |

|

|

| |

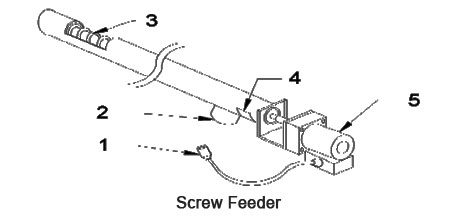

Screw Feeder |

|

|

The screw feeder is intended for supplying pellets from the bunker to the burner. It consists of the following elements: |

|

| |

|

|

| |

|

|

| |

|

|

|

1 - power cord, 2 - pellet outflow tube, 3 - pellet intake holes, 4 - safety cutoff, 5 - engine. |

|

|

The screw feeder is connected to the burner with using a special hose made of fusable material what ensures safety factor and prevents from inverted flame. With the help of the mounting kit the screw feeder is fastened to the wall, bunker or ceiling depending on installation area conditions. Picture 3 shows correct location of the screw feeder towards the horizon and the burner. It is necessary to meet the following recommendations during installation and operation process:

- Pellet intake hole shall be located upward vertically, and nothing should cover (overlap) it.

- Pellet outflow tube shall be located downward vertically.

- Screw feeder shall be located towards horizon at an angle of 30-45°

- Horizontal distance between the pellet outflow tube of the screw feeder and the burner pellet receiver tube shall be not less than 200 mm, at the same time, the hose for hooking up the screw feeder and the burner shall not be slacking or having curves of more than 30°, this will ensure unobstructed supply of pellets. |

|

| |

|

|

| |

|

|